TRANSMISSION "TERNA"

The “underground link between the Favazzina arrival locations of the submarine cables and the vertical of the Scilla electric power station” is a work that is an integral part of the new double-circuit transmission line, 380 kV, AC, Sorgente-Rizziconi, to link Sicily and Calabria.

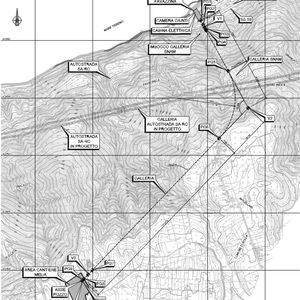

The designed works consist mainly of a sub-horizontal tunnel, 2,842 metres in length, excavated by blind hole, and a vertical shaft more than 300 metres deep, which will make it possible to bring the cables from the sea arrival in Favazzina to the Scilla electric power station, located at an elevation of approximately 630 metres above sea level. The first section of tunnel, 100 metres in length, was excavated by traditional method to allow a part of the TBM to be inserted, and the railway and road underpass and the first, more superficial section of lost and altered rock to be overcome.

In this work, CIPA took part by building the first 100 metres of the Favazzina tunnel by traditional excavation, the vertical shaft (pre-lining and final lining) and connection with the tunnel.

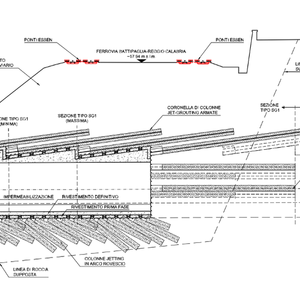

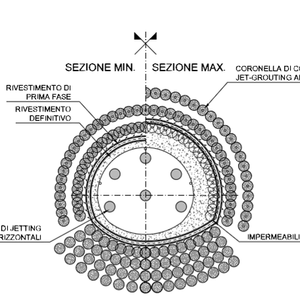

The sub-horizontal tunnel starts near the Favazzina beach. In its layout, the route develops with an initial, straight section of approximately 500 metres in length, roughly perpendicular to the coastline, then with a large curve to the right (R=500 m) which runs for about 630 m in length on plan, and lastly with a straight section for about 1,710 metres in length until crossing the shaft. The tunnel crosses, for almost its entire length, the crystalline/metamorphic base of the Calabrian arch. Only in approximately the first 30-40 metres starting from the entrance on the Favazzina coastline, the tunnel was excavated in the loose ground that constitutes the railway embankment of the Battipaglia-Reggio Calabria line and the embankment of national road S.S.18. Along this section, the tunnel is excavated with section type SG1, i.e. truncated cone section, with pre-consolidation at the edge of the cavity consisting of a ring of jet-grouting reinforced with steel forepoling, and consolidation of the face and in invert with jet grouting alone. For this section the excavation was carried out in full section, by mechanical equipment using no explosives with feed of approximately 1.00 metre, to permit the immediate installation of the pre-lining consisting of steel ribs and shotcrete.For the remaining section, which is to say 60-70 metres, section type SG2, which is to say tunnel in current section, was adopted, without consolidation, excavated by explosive, without prejudice to the pre-lining with ribs and shotcrete. The final lining, after the waterproofing was put in place, was done in two main phases, the first in the first 30-40 metres completing section SG1 and the rest upon reaching 100 metres of excavation, corresponding to the completion of section SG2.

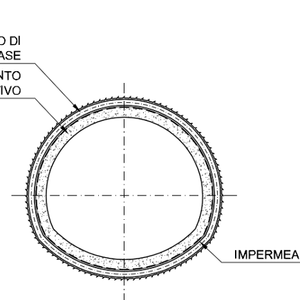

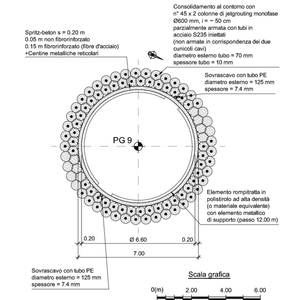

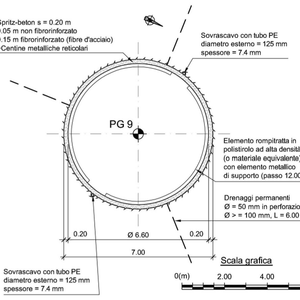

The vertical shaft starts inside the Melia electric power station, owned by TERNA, and joins the tunnel described above. The excavation of the shaft, marked by a depth of 300 metres and an excavation diameter of approximately 7 m, was done by traditional method from top to bottom, with maximum feeds equal to approximately 2.00 metres, enabling the immediate installation of the pre-lining consisting of reticular ribs, 100/20/30/10, placed at a pitch from 1.00 m to 0.50 m in correspondence with the connection chamber described below, and shotcrete with welded wire mesh for a total pre-lining thickness of 0.20 m. The water bailing system used consists of dual pumps in series, housed in the niches made for this purpose in the shaft about every 50 metres and was sized to handle inrush in volumes of up to 40 litres/second. The shaft’s activities were begun in April 2012 with the building at its entrance of a concrete collar with mixed steel/VTR reinforcement. The excavation continued in correspondence with the initial section in sand, for about 60 m with section type SP1, which called for pre-consolidation of the edge of the excavation using two jet-grouting rings partially reinforced with steel forepoling. Since the initial section involved soil consisting of weakly cemented sands, it was possible to conduct the excavation without using explosives, while adopting this section type to a depth of approximately 80 metres.The shaft’s excavation continued after 80 metres with the use of explosives (SP2), with the drill and blast method by a Jumbo with two hydraulic drifters.

Furthermore, section type SP2 calls for a permanent drainage system and the use of inter-tie elements embedded within the final lining. A crane was used to pull up and down the equipment to be employed in the excavation and the materials to be used in the various working phases, as well as allowing it to handle the metal platform at the service of the working operations. The shaft excavation was completed in October 2013.

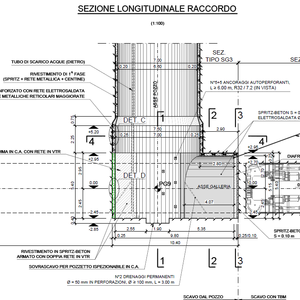

In the final metres of the shaft’s excavation, the activities prerequisite for building the connection with the tunnel, as described below, were carried out:

• Reinforced concrete reinforcement ring;

• Continuation of the shaft excavation and securing of the excavation walls;

• Excavation and consolidation of the tunnel (SG3) constituting the connection chamber;

• Building of a diaphragm in reinforced concrete with VTR, against which the TBM completes the excavation work;

• Basic casting of reinforced concrete where the TBM will be transported;

• Construction of two piers in reinforced concrete (curved) beneath the reinforcement ring;

• Installation of the final lining of the connection tunnel;

To date, the activities for the tunnel (SG3) are in progress; however, the construction of the shaft’s final lining, planned in fibre-reinforced concrete, will be marked by structural disconnections done with inter-tie elements in high-density polystyrene.

The casting of the final lining equal to 35 cm will take place in re-ascent with the aid of a continuously sliding formwork, leaving the climbing bars immersed in the lining. Planned production is 5 m/d.

Sub - Horizontal Tunnel - Favazzina

Vertical Shaft

Tunnel - Shaft connection

Job worksheet

Place: Italy - Scilla

Period: February 2012 - August 2016

Client: Terna S.p.A.

Value: 43.287.000 EUR

SOA categories:

OG4 VIII |

OG1 VIII |

OS3 III |

OS30 IIIbis

Status advancement work: 100%

links

photo

album

album

New double circuit transmission line 380 kv

New double circuit transmission line 380 kv