VARIANTE DI VALICO

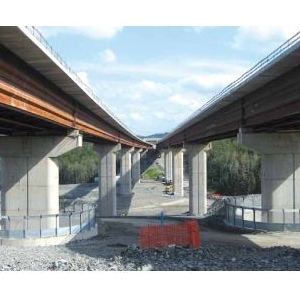

Since 2006, Cipa has taken part in the construction of the “Variante di Valico,” in order to strengthen the A1 motorway between Sasso Marconi and Barberino, where we have built structural and drainage shafts in considerable number - 34 of them - as well as the final lining of part of the main tunnel.

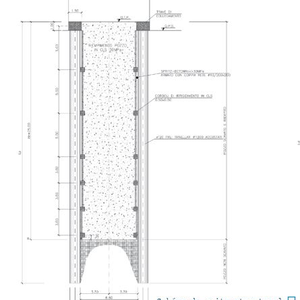

The structural shafts were built as part of the construction of the viaducts, excavating by bucket and concrete breaker, and making stiffening and lining with welded wire mesh and quick setting shotcrete. At the end of the excavation operations, the shafts were filled with concrete.

These are the structural shafts that were made, and their afferent viaducts.

Casaglia Viaduct: 10 shafts with an excavation diameter of 8.30 metres and an average depth of 24 metres.

• 2 shafts with an excavation diameter of 12.60 and a depth of 42 metres.

Stura Viaduct

• 4 shafts with an excavation diameter of 11.00 metres and an average depth of 16 metres.

Montecarelli Viaduct: 2 shafts with an excavation diameter of 7.50 metres and a depth of 17 metres.

• 2 shafts with an excavation diameter of 9 metres and a depth of 17 metres.

Le Bandite Viaduct: 2 shafts with an excavation diameter of 11.00 metres and a depth of 15 metres.

• 2 shafts with an excavation diameter of 9.00 metres and a depth of 17 metres.

• 2 shafts with an excavation diameter of 7.50 metres and a depth of 17 metres.

The structural drainage shafts were made as part of the construction of the Poggiolino station, excavating by bucket and concrete breaker, lining with welded wire mesh and steel ribs, quick setting shotcrete, reinforcement and concrete casting in lift with climbing formwork. When the drilling was performed for the hydraulic drainage connections between the shafts, our working operations were concluded.

Poggiolino Station: Construction of 8 shafts with an excavation diameter of 9.00 metres and a depth of 22 metres.

As part of the working operations for the main tunnel, we carried out the final lining of about 1,800 metres of the tunnel by hydraulic steel formwork, of 18 linking bypasses between the two tubes, and 14 widenings with lay-by, using curved precast reinforced concrete slabs, positioned on site by machines with specially designed equipment, behind which the concrete was cast that constitutes the final lining of the tunnels, which completely incorporated the slabs.

Job worksheet

Place: Italy - Castiglione dei Pepoli

Period: March 2007 - January 2012

Client: Todini Costruzioni Spa

Status advancement work: 100%

documents

photo

album

album

Book _Variante di Valico

Book _Variante di Valico